SERVICES

■ENGINEERING DESIGN

Leveraging the design and analysis technologies cultivated through motorsport development, Dome pursues optimized solutions across a wide range of fields not limited to only racing or advanced development vehicles. Our expertise includes weight reduction, enhanced strength and rigidity, labor efficiency, and miniaturization by applying our extensive knowledge in aerodynamics, composites, and vehicle dynamics.

■CARBON COMPOSITES

Anticipating that carbon fiber (CFRP) would become a core technology in racing car development, Dome has been a pioneer in CFRP component design and manufacturing since the late 80s, by collaborating with Japanese material manufacturers. This expertise enabled the creation of the first full carbon monocoque for a Gr.C car and the production of vehicles for series such as Formula 3000. The number of racing cars developed using CFRP places Dome among the world’s leading constructors in terms of technical capability. In recent years, we have also been advancing the development of composites using natural materials.

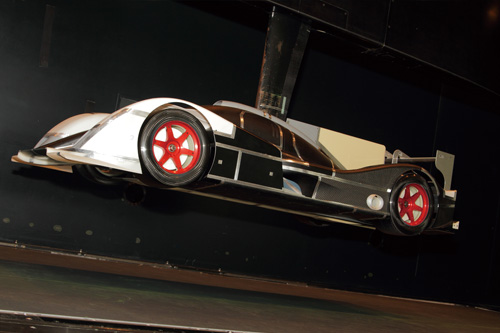

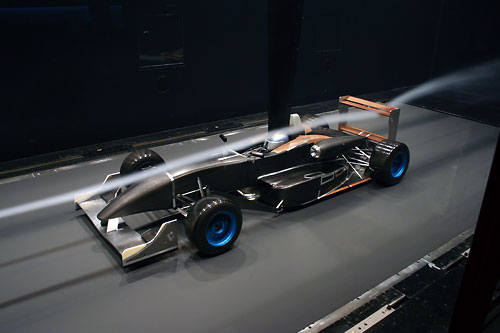

■AERODYNAMICS

Dome’s racing car development has long emphasized aerodynamic testing, beginning with our first super sports car, the “Dome Zero.” In 1987, we built a 25% scale wind tunnel in Ohara, Kyoto, followed by a 50% scale facility with a moving belt in Maibara, Shiga Prefecture in 2000. These systems and equipment are still regularly updated more than 20 years later, making it one of Japan’s leading 50% scale wind tunnel facilities. Dome will continue to apply its accumulated expertise to advance aerodynamic development.

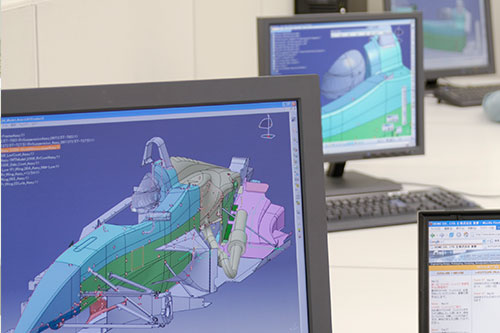

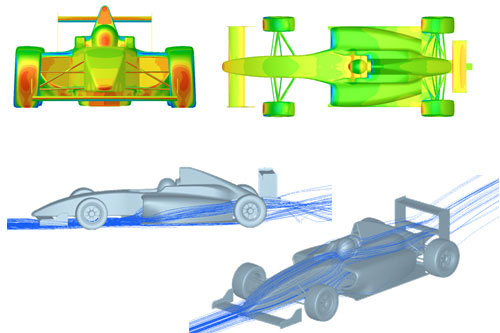

■TESTING & ANALYSIS

At Dome, we leverage Computational Fluid Dynamics (CFD) to pursue highly effective and efficient aerodynamic development, enhancing accuracy by combining it with wind tunnel testing. Simultaneously, we employ the Finite Element Method (FEM) for structural analysis. In the development of carbon composite products, we achieve superior results by integrating FEM-based optimized design with actual rigidity and strength testing.

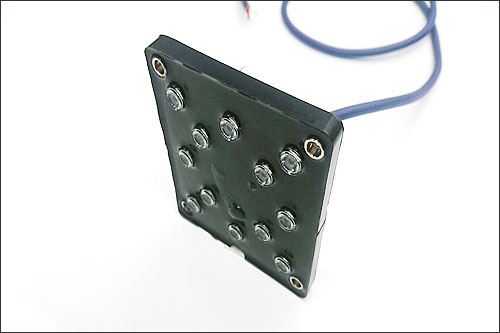

■ELECTRICAL COMPONENTS DESIGN

Dome has also developed various electronic components for race cars in-house, including control units , fuel delivery systems, and electrical equipment. In January 2025, our newly developed rain lamp for racing cars received FIA certification (8874-2019).

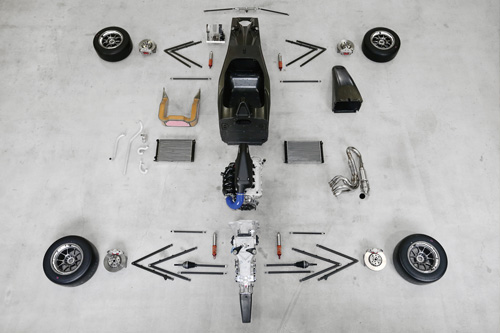

■RACING CARS

Dome’s racing car development primarily consists of commissioned projects from automobile manufacturers as well as in-house initiatives. Over the years, we have developed and sold vehicles including Formula 3 and Le Mans race cars, which were originally created as in-house projects and subsequently manufactured and sold upon customer requests.

In 2013, following the establishment of the FIA-F4 regulations, Dome decided to fully enter the market for commercial racing cars, developing the FIA-F4 chassis as a commercially available race car in 2015.

■MOTOR SPORTS

While Dome’s core business is as a constructor, there are many commonalities between the technologies used to develop and to operate racing cars. Dome’s technically advanced and scientific approach to racing has earned high recognition in the motorsport community.

■CAR DEVELOPMENT

Dome can develop and produce a wide range of vehicles, including design models, prototypes, and production cars. Since our establishment in 1978, we have undertaken the development and production of more than 100 vehicle models for various automobile manufacturers, specializing in chassis development and the creation of full-scale running models.