DOME TUNNEL / FURYUSHA

Ever since their first creation– the Dome-Zero super sports car– Dome’s aerodynamic development has been characterized by the maximization of aerodynamic performance based on wind tunnel testing. This profound expertise in aerodynamics has become a crucial element which supports the company’s technical advantage.

Drawing on the extensive knowledge accumulated through wind tunnel testing since its founding, as well as its in-house development and operation of wind tunnel facilities, Dome has applied their composite technology cultivated through chassis development to build Furyusha, the ideal automobile model wind tunnel testing facility in Maibara City, Shiga Prefecture. This facility enables 50% scale wind tunnel experiments and boasts a horizontal Göttingen-type closed-circuit tunnel with a total length of 99 meters, one of the largest of its kind for automotive model testing in Japan.

Furyusha has been designed to not only support Dome’s racing car development as a constructor, but also to provide further advantages for aerodynamic and design development in the new era of mobility, including the electrification of automobiles.

By incorporating CFD (Computational Fluid Dynamics), the efficiency of aerodynamic development is further enhanced. At the same time, visual analysis of airflow provides insights that directly lead to design improvements, making it an indispensable tool for competitive aerodynamic development.

Furthermore, the facility is flexible enough to accommodate not only automobiles but also motorcycles, racing bicycles, racing wheelchairs, drones, and more– thereby contributing to aerodynamic development across a wide range of mobility fields.

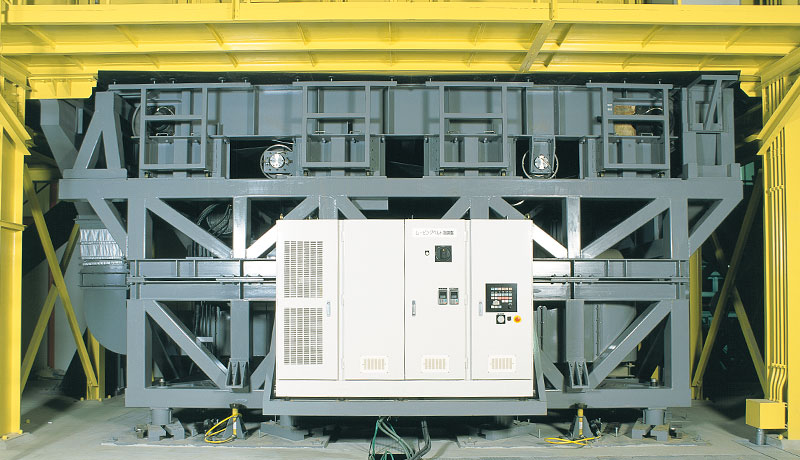

■MAIN FAN

The main fan is an axial-flow type which operates to produce winds up to 60m/s

■FACILITY CONSTRUCTION

The steel-framed plate structure (plate thickness: 9mm) and a horizontal closed return Gettigen type wind tunnel has been installed indoors, with an air duct length of 99m. Wind temperatures can be steadily regulated to optimize the laboratory environment, and sound insulation is provided to preserve the surrounding environment.

■TEST AREA

The test area is 2.75m wide by 2.5m high, sufficient for testing 50% F1 models and similar vehicles. Being 8m long, the test area is also sufficient for tandem testing and turbulence simulations.

■CONTRACTION CONE

A high contraction ratio of 8.3 ensures stable airflow and uniform temperature distribution.

■COOLING SYSTEM

The facility includes a cooling system capable of wind temperature control within a range of 25±3℃ (at a wind speed of 45 m/2), which is sufficient for consistent measurement.

■MOVING BELT

A moving belt, 2m wide and 5.5m long, is installed on the floor of the test section. This belt runs at up to a maximum wind speed of 60m/s, the fastest belt speed achieved in Japan. A boundary-layer suction unit is installed at the front end of the belt, and the belt is installed on a turntable for testing involving a yaw within ±5 degrees, with tire arms to affix models.